Please call Gage-Lab Products today to find a machine that fits your needs. (801) 716-2972

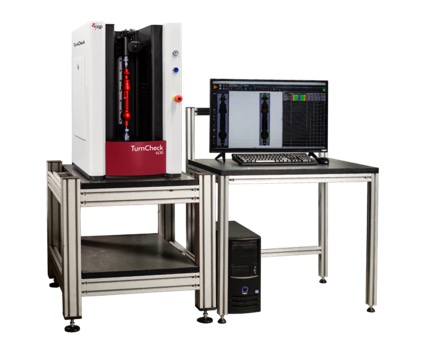

TurnCheck™ systems are precision optical instruments designed to measure shafts and other cylindrical parts. Each member of the TurnCheck family is built for ease of use and consistent accuracy, even in difficult shop-floor conditions.

TurnCheck systems are built for the people who use them: With advanced optics, rugged materials, and intelligent controls to make set up and measurements fast, accurate and easy.

Measuring Range (mm)

300 L x 60 Ø

TurnCheck™ Series-6 systems are precision optical shaft measuring instruments designed for shop floor environments. Rugged and reliable, TurnCheck accommodates parts up to 300 mm in length. TurnCheck Series-6 systems include:

- Completely telecentric, large field of view optical system

- The ability to measure diameters as large as 60 mm and lengths up to 300 mm

- Fast, easy measurements of all critical dimensions of turned parts, from simple lengths and diameters to advanced profile fitting and form

- Optional ±15° of motorized helix angle adjustment for correct thread form measurements

TurnCheck system software offers advanced image analysis technology for high speed optical measurement. Automatic feature extraction immediately finds and measures all part features in a single scan. TurnCheck offers fast and precise measurement of known and unknown parts without programming or a CAD model. TurnCheck offers integral GD&T and best-fitting, and can output all point data for external analysis or reverse engineering.

The movable tailstock assembly is designed to be easily operated with one hand for precision mechanical alignment of the workpiece. Additional optional workholding kits that fit into the spindle accommodate workpieces that do not have centers.

Measuring Range (mm)

10|40 – 400 L x 100 Ø

10|60 – 600 L x 100 Ø

10|80 – 800 L x 100 Ø

TurnCheck™ Series-10 systems offer a fast, easy way to measure shafts, cylinders and other turned, ground or extruded parts. Just place the part and press GO.

TurnCheck Series-10 systems are precision optical measuring instruments designed for shop floor environments. TurnCheck systems are rugged and reliable, accommodating parts up to 175 mm diameter by 800 mm in length. TurnCheck will scan and measure a part in seconds using its telecentric, large field of view optical system. With 100 mm wide field of view and vertical range of 400, 600 or 800 mm, TurnCheck Series-10 systems can handle just about any turned or ground part. TurnCheck software allows easy measurement of diameters, lengths, distances, angles, radii, form, position, cylindricity, and runout – and can output point data for external analysis.

The movable tailstock assembly is designed to be easily operated with one hand for precision mechanical alignment of the workpiece. Additional optional workholding kits that fit into the spindle accommodate workpieces that do not have centers. Granite base support for rotary provides a rigid base and isolates vibration