Please call Gage-Lab Products today to find a machine that fits your needs. (801) 716-2972

NON-CONTACT LASER PROFILING SYSTEMS

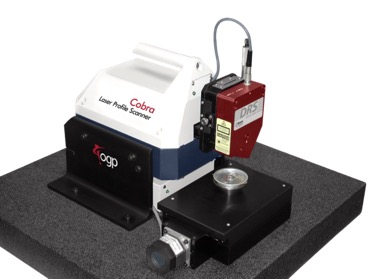

Cobra™ Laser Profiling systems from OGP use low-power laser lights to measure height, area, slope, and radius. These laser profilers are ideal for a variety of applications where non-contact measurement is critical to ensure integrity for your parts while measuring to precise accuracies.

Standard:

Scan length – X-axis NA, Y-axis 50 mm

Z-axis adjustment range – 50 mm

Non-Contact Profiling

Cobra™ 2D is a portable laser scanning system that provides high resolution linear profiles. Because Cobra uses low power laser light, it is ideal for fragile or pliable parts that have critical surface contours. Cobra is quick and allows easy measurement of height, length, slope, and radius. Cobra 2D measures surface height while scanning along its Y-axis

Accurate surface profiles – Cobra™ provides accurate surface height information as its lowpower laser scans over a surface

Selectable laser sensors – Available DRS™ lasers offer a range of resolutions and standoff distances to satisfy a variety of applications

Real-Time Imaging – Optional video camera for on-axis imaging of the part being measured. See the laser spot pass over the surface of the part as it is measured. On-axis LED surface illumination under 15x magnification for perfect image contrast, adjustable through Scan-X

Standard:

Scan length – X-axis 100 mm, Y-axis 50 mm

Z-axis adjustment range – 50 mm

Cobra™ 3D provides area profiling for more information. Cobra 3D measures profiles in X & Z axis and has laser scanning resolution to 5 µ inches. Cobra 3D is versatile and can be used on a benchtop or placed directly on a part.

Accurate surface profiles – Cobra™ provides accurate surface height information as the low power laser scans over a surface

Selectable laser sensors – Available DRS™ lasers offer a range of resolutions and standoff distances to satisfy a variety of applications

Real-Time Imaging – Optional video camera for on-axis imaging of the part being measured. See the laser spot pass over the surface of the part as it is measured. On-axis LED surface illumination under 15x magnification for perfect image contrast, adjustable through Scan-X