CMM Hardware

Renishaw offers the world's leading range of touch-trigger and scanning measurement systems for CMMs.

5-Axis Systems:

Unlike conventional CMM measurement methods, Renishaw's 5-axis technology uses the synchronized motion of CMM and the head axes to minimize dynamic errors at ultra-high measuring speeds.

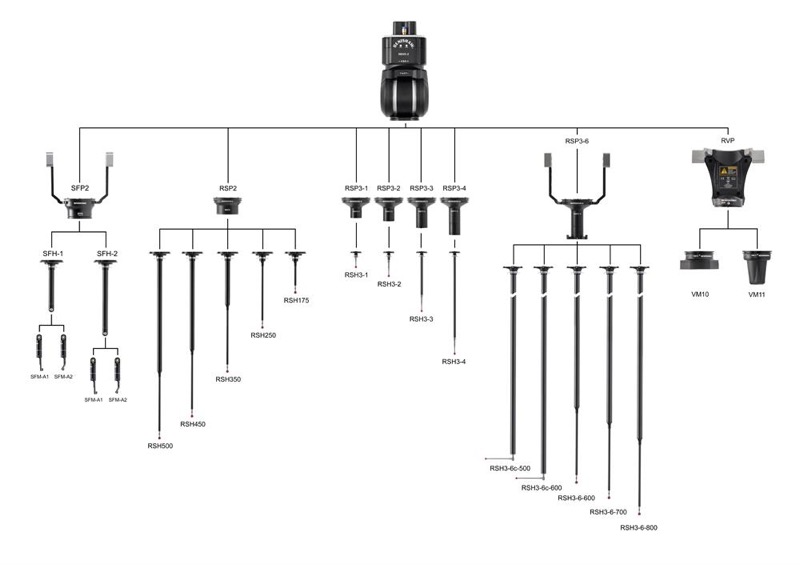

REVO 5-AXIS MEASUREMENT SYSTEM

A REVO® system delivers high performance scanning, non-contact inspection and surface finish analysis on a single CMM. This system uses synchronized motion and 5-axis measurement technology to minimize the dynamic effects of CMM motion at ultra high measurement speeds. This is achieved by letting the REVO-2 head do the fast demanding motion while the CMM moves in a linear slow fashion. The use of a flexible tip-sensing probe further adds to the system's accuracy and performance. The removable probe system, used in conjunction with a low cost changer, provides added system flexibility. Renishaw's 5-axis high-speed, high-accuracy measurement techniques offer a wide range of benefits resulting in significant throughput improvements.

PH20 5-AXIS TOUCH-TRIGGER SYSTEM

Easy access to features at any angle

PH20's infinite positioning capability guarantees optimal feature access, minimising stylus changes. The 5-axis simultaneous motion allows larger parts to be measured on the CMM by minimising the space required around the part for head rotation. PH20 automatically aligns itself with the part co-ordinate system, avoiding stylus collisions and the requirement for accurate fixtures.

Faster calibration

The unique ‘inferred calibration' technique developed for PH20 determines the head orientation and probe position in a single operation, allowing subsequent measurement at any head angle. Further modules only require a few touches on the calibration sphere before use (enhanced metrology performance is available if needed by calibrating the probe tip at the feature orientation).

These dramatic time savings accumulate as the calibration process is repeated on a regular basis to comply with quality procedures or following a probe crash.

Integral industry standard TP20 probe

Users of the PH20 probe head will immediately have access to the range of proven TP20 probe modules, providing a wide selection of trigger forces, directional sensing options and extensions to meet application requirements. The detachable modules provide crash protection and can be automatically changed using the TCR20 change rack.

Contact us today for all your measurement needs!

Back To Renishaw